Factors that affect Light Reflection

Reflection

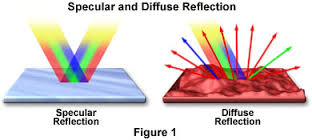

[: is either specular (mirror-like) or

diffuse (retaining the energy, but losing the image)]

Surface type- reflectivity

is a directional property; most surfaces can be divided into those that give

specular reflection and those that give diffuse reflection. Most objects have

some mixture of diffuse and specular reflective properties.

Refractive Index (RI) - by

measuring the angle of incidence and angle of refraction of the light beam, the

refractive index n can be determined. Refractive index of materials varies with

the frequency of radiated light.

Reflective Value (RV) - the

reflective value of a colour indicates how much light and heat is reflected

back from the colour surface.

Light reflectance value (RV) is a numerical

rating assigned by paint manufacturers to each colour they make. This number is

a scientifically determined assessment of the amount light and heat that colour

will reflect on a scale of 0 to 100.

Refractive Index (RI) or Haze Value -when light strikes the surface of a material it bounces

off in all directions due to multiple reflections

Light Reflective Value (LRV) –the

average blackest black has a light reflection value (LRV) of approximately 5%

and the purest white is approximately 85%. Some yellows can measure up into the

80's or 90's as well. All colours fit in between these two extremes.

Distinctness of image (DOI) - the

appearance of reflecting objects is determined by the way the surface reflects

incident light. The reflective properties of the surface can be characterized

by a closer look at the (micro)-topography of that surface.

Structures on the surface

and the texture of the surface are determined by typical dimensions between

some 10 mm and 0.1 mm (the detection limit of the human eye is at ~0.07 mm).

Smaller structures and features of the surface cannot be directly detected by

the unaided eye, but their effect becomes apparent in objects or images

reflected in the surface. Structures at and below 0.1 mm reduce the DOI

structures in the range of 0.01 mm induce haze and even smaller structures

affect the gloss of the surface.

DOI meter measures the gloss

and the distinctness of image (DOI) of a painted surface for quality evaluation

of the finish. A signal is obtained by a prior method of focusing the reflected

image of a moving shutter onto a slit and measuring the light passing through

the slit. The rate of increase of the resulting signal is used as a measure of

DOI. The same signal is integrated over a pre-set time period covering the

upper part of the signal rise to yield a value proportional to gloss.

Calorimetric and colour theory -

colourfulness, chroma, and saturation are related but distinct concepts

referring to the perceived intensity of a specific colour.

As can be seen there are

many factors to consider as to what constitutes optimum surface light

reflection, one factor that has the most profound affect is light reflective

value (LRV) or Surface colour

Optimal Light Reflection

Requirements:

•

Clean-washed to remove

oxidation, surface dirt and grime, tar and road film

•

Reflectivity – that comes

from a clean and level surface

•

Gloss-that comes from oils

and polymers with their ability to reflect light with a minimum of light

diffusion to produce surface shine

•

Optical depth-comes from an

applied product that is two-dimensional, so that light is reflected from both a

high and low source, (i.e. a Carnauba waxes ‘egg-grate’ type structure) which

‘distorts’ reflected light to produce a rippling effect (warmth)as opposed to a

polymer elongated and ‘chain-link’ type mesh, which exhibits a flat ‘mirror’

like shine

•

Optimising light refraction

-apply product in ‘direction of airflow’, horizontal surfaces hood to trunk,

vertical surfaces front to back. This application technique affects the paints

optical properties by optimising light refraction and the reflectivity of the

bodylines and contours of the vehicle

•

Transparency-or clarity of

the applied product, which will enable all the above components to be clearly

visible

Light Reflection

The way light is reflected

from a paint surface affects the vehicles appearance after it is detailed. Reflection of light is either Specular (mirror-like) or Diffuse (retaining the energy, but losing the image) depending on the nature of the surface. It is also possible for reflection to occur from the

surface of transparent media, such as water or glass.

Transverse Waves - light

is a form of wave motion, but as it travels at such a high speed it isn't

possible to observe directly the way in which the moving waves vibrate.

However, experiments show that the waves vibrate at right angles to the

direction of the light beam, and because of this light is said to consist of

transverse waves.

Laws of reflection- if the reflecting surface is very

smooth, the reflection of light that occurs is called specular or regular

reflection. The laws of reflection are as follows:

The incident ray -the reflected ray and the normal to the

reflection surface at the point of the incidence lie in the same plane.

The angle - which the incident ray makes with the normal,

is equal to the angle which the reflected ray makes to the same normal.

The way light is reflected

from a paint surface affects the vehicles appearance after it is detailed. Reflection of light is either Specular (mirror-like) or Diffuse (retaining

the energy, but losing the image) depending on the nature of the surface. It is also possible for reflection to occur from the

surface of transparent media, such as water or glass.

1.

Paint colours reflect light differently, i.e. a white or silver

will reflect specular light. Darker colours i.e. red, black, etc. absorb light

and therefore the reflected light is diffused.

2.

Metallic paint reflects light from the flakes, which create

micro mirrors and add a distinctive ‘shine’

3.

A polymer sealant or a nano coating product are more suited to

the reflectance properties of light colours. An organic wax suit the reflective

properties of darker colours due to its imparted jetting (the so-called wet-look)

Surface type

Reflectivity is a

directional property; most surfaces can be divided into those that give

specular reflection and those that give diffuse reflection. Most objects have

some mixture of diffuse and specular reflective properties.

For specular surfaces-

such as glass or polished metal, reflectivity will be nearly zero at all angles

except at the appropriate reflected angle.

For diffuse surfaces -

such as matte paint, reflectivity is uniform; radiation is reflected in all

angles equally or near-equally. Such surfaces are said to be Lambertian.

Spatial

reflection – [: direction of

incoming light (the incident ray), and the direction of outgoing light

reflected (the reflected ray) make the same angle with respect to the surface

normal, thus the angle of incidence equals the angle of reflection; this is

commonly stated as θi = θr.]

The perfect, mirror-like

reflection of light from a surface, in which light from a single incoming

direction is reflected into a single outgoing direction the best example of

spatial reflection is seen when reflected from a flat level surface.

If the surface is perfectly

flat, light will be reflected to produce a mirror image of the surface. But if

there you have matte paint or are imperfections such as swirls, surface

contaminants, orange peel, or oxidation (dull, opaque or unlevelled paint)

light is refracted and the reflected light becomes distorted, which mutes the

shine.

Diffuse

reflection [:

incoming light is reflected in a broad range of directions] [1]

When light strikes the

surface of a material it bounces off in all directions due to multiple

reflections. The most familiar example of the distinction between specula and

diffuse reflection would be glossy and matte paints.

While both exhibit a

combination of specula and diffuse reflection, matte paints has a higher

proportion of diffuse reflection and glossy paints have a greater proportion of specula

reflection.

Refraction

[:

index of refraction n = c / v]

When we talk about the speed of

light, we're usually talking about the speed of light in a vacuum, which is

3.00 x 108 m/s. When light travels through something else, such as glass,

diamond, or plastic, it travels at a different speed. The speed of light in a

given material is related to a quantity called the index of refraction, n,

which is defined as the ratio of the speed of light in vacuum to the speed of

light in the medium: index of refraction: n = c / v [1]

When light travels from one medium to

another, the speed changes, as does the wavelength, the index of refraction can

also be stated in terms of wavelength: Although the speed changes and wavelength

changes, the frequency of the light will be constant. The frequency,

wavelength, and speed are related by Snell’s law:

Refractive Index

By measuring the angle of

incidence and angle of refraction of the light beam, the refractive index n can

be determined. Refractive index of materials varies with the frequency of

radiated light.

This results in a slightly

different refractive index for each colour. The index of refraction

characterizes not only the light propagation speed, but also the bending angle

and the amount of radiation transmitted and reflected by a material

Reflective Value

[: a

measurement commonly used in interior decorating and design, which expresses

the percentage of light that is reflected from a surface]

The reflective value (RV) of

a colour indicates how much light and heat is reflected back from the colour

surface. Light reflectance value (RV) is a numerical rating assigned by paint

manufacturers to each colour they make. This number is a scientifically

determined assessment of the amount light and heat that colour will reflect on

a scale of 0 to 100. Zero assumed to be an absolute black and 100% being an

assumed perfectly reflective white. An absolute black or perfectly reflecting

white do not exist in our everyday terms.

Polymer sealant- comprises

an open linked molecule, which forms a bond with the paint; these open linked

polymer molecules join together to create an elongated mesh like effect that

reflects light efficiently due to their inherent flat surface. Because they are

usually very transparent they transmit the surface colour faithfully, but they

have very little depth resulting in what is perceived as a very bright, but

flat silver glow

A wax or sealant can only

reflect what is underneath it, so a clean, level well-prepared surface is the

most important consideration (85% of a surfaces reflectivity is due to its

preparation) along with applied product clarity. If you apply a product over a

surface that is dirty or one that has surface imperfections a wax or sealant

will not hide or disguise (unless they contain fillers) but highlight them as

the light will reflect differently from the rest of the paint surface.

Refractive Index

Refractive Index (RI) or

Haze Value -when light strikes the surface of a material it bounces off in all

directions due to multiple reflections. The most familiar example of the

distinction between specula and diffuse reflection would be a polymer and a

Carnauba wax.

While both exhibit a

combination of specula and diffuse reflection, Carnauba wax has a higher

proportion of diffuse reflection and Polymers have a greater proportion of

specula reflection.

•

Mirror (specular) – RI: 1.00

•

Water - RI: 1.33.

•

Carnauba wax (diffuse) – RI: 1.45

•

Poly (Dimethalsiloxane) (specula) – RI: 1.48

The Angle of Rejection

When light reflects off of a

surface such as a mirror, two angles are created from the light’s path and the

surface of the mirror: the angle of incidence and the angle of reflection.

Light Reflective Value (LRV)

The average blackest black

has a light (polarized) reflection value (LRV) of approximately 5% and the

whitest white (un-polarized reflection) is approximately 85%. Some yellows can

measure up into the 80's or 90's as well. All colours fit in between these two

extremes.

A colour with an LRV of 50

will reflect 50% of the light that falls on it, and one with an LRV of 23 will

reflect 23% of the light, and so on.

Think of a reflective value as a numerical

version of a grey value scale for colours, roughly like this-

Pure White -

100, White -95, Light -

80, Low Light - 65, Medium -

50, High Dark - 35, Dark – 20

It would take too long to

list individual OEM colours, i.e. Arctic White, Speed Yellow, Guardsman Red,

Onyx Black, etc. so you’ll need to interpolate

As can be seen there are many factors to consider apart from

index numbers

Shine vs. Gloss

The reflective value (RV) of

a colour indicates how much light is absorbed or diffusely scattered dependent

on the colour.

·

High reflective

value (i.e. white or very light colours) exhibit

Spatial (Shine) reflection; a

mirror-like reflection from a surface

·

Low reflective

values (i.e. darker colours (black) exhibit a

diffused (Gloss) reflection; incoming light is reflected in a broad

range of directions

Backlighting

Clear coated paints show minor

swirls and scratches more readily than pigmented paint (single stage) due to an

optical effect called backlighting. Light penetrates the clear coat and is

reflected from pigmented paint (colour coat) which in turn reflects any

imperfections in the surface of the clear coat, making them highly visible. As

you drive towards the setting sun or oncoming

headlights on a rainy night, every speck of dirt, smudge or smear on your

windshield is suddenly very obvious. They are much more noticeable when

sunlight or oncoming headlights back-light them.

Light Coloured Surface

For secular surfaces, such as

glass or polished metal, reflectivity will be nearly zero at all angles except

at the appropriate reflected angle. For diffuse surfaces, such as matt white

paint, reflectivity is uniform; radiation is reflected in all angles equally or

near-equally. Such surfaces are said to be Lambertian. Most objects have some

mixture of diffuse and secular reflective properties.

Reflection

Reflection and refraction are terms that describe

how is reflected from a surface; refraction or diffused reflection) changes due to the

microscopic irregularities of the surface, each medium has a different

reflective value.

As light travels and strikes the paint surface, it travels through the wax or

sealant then the clear coat it reflects at different angles due to their

differing reflective values.

It will also

reflect back at certain points where the angle of incidence equals the angle of

reflection. As the photons of light gain proximity they become more brilliant.

To enhance gloss you need to reflect as much light as possible, without

interfering with that proximity or brilliance.

Proving the reflective surface is level, a rotary

would produce a circular pattern, and a random orbital would produce an

elliptical pattern, which would tend to separate the photons, thus reducing

brilliance, while the circular would combine and concentrate them, thus

enhancing gloss.

Gloss

Meter

Intensity is dependent on

the material and the angle of illumination. In case of non-metals (coatings,

plastics) the amount of reflected light increases with the increase of the

illumination angle. The remaining illuminated light penetrates the material and

is absorbed or diffusely scattered dependent on the colour.

Gloss Measurement

A

gloss meter is an instrument which is used to

measure specular reflection gloss of a surface. Gloss is determined by

projecting a beam of light at a fixed intensity and angle onto a surface and

measuring the amount of reflected light at an equal but opposite angle.

Surface gloss [: is considered to be the amount of

incident light that is reflected at the specular reflectance angle of the mean

of that surface.]

Specular

- means mirror-like and specular gloss is defined as the

perception by an observer of the mirror-like appearance of a surface. In truth

this appearance cannot be quantified: all that can be done instrumentally is to

measure the amount of incident light that is reflected at a defined angle (or

range of angles).

Measurement angle refers to

the angle between the incident and reflected light. Three measurement angles

(20°, 60°, and 85°) are specified to cover the majority of industrial coatings

applications. The angle is selected based on the anticipated gloss range, as

shown in the following table.

For example, if the

measurement made at 60° is greater than 70 gloss units (GU) the measurement

angle should be changed to 20° to optimise measurement accuracy. Three types of

instruments are available on the market: 60° single angle instruments, a

combination of 20° and 60° and one type that combines 20°, 60° and 85°.Materials

with a higher refractive index can have a measurement value above 100 GU, e.g.

films. In case of transparent materials, the measurement value can be increased

due to multiple reflections in the bulk of the material. Due to the high

reflection capabilities of metals values of up to 2000 GU can be reached.

Gloss - is a visual impression

resulting from surface evaluation? The more direct light reflected, the more

obvious the impression of gloss will be. Smooth and highly polished surfaces

reflect images distinctly. The incident light is directly reflected on the

surface, i.e. only in the main direction of reflection. The angle of incidence

is equal to the angle of reflection.

Gloss units - the measurement scale, GU,

of a gloss meter is a scaling based on a highly polished reference black glass

standard with a defined refractive index having a specular reflectance of 100GU

at the specified angle. This standard is used to establish an upper point

calibration of 100 with the lower end point established at 0 on a perfectly

matte surface. This scaling is suitable for most non-metallic coatings and

materials (paints and plastics) as they generally fall within this range.

Two high gloss surfaces can

measure identically with a standard gloss meter but can be visually very

different. Instruments are available to quantify orange peel by measuring

Distinctness of Image

(DOI) or Reflected Image Quality

(RIQ) and Haze.

Rhopoint IQ Flex 20 is

designed for the measurement of small and curved surfaces. This instrument

quantifies surface quality problems such as orange and peel and haze that are

invisible to a standard gloss meter and profiles how light is reflected from a

surface.

Previously gloss meters were

only available for measuring flat surfaces, this technology is now available in

a new format specifically designed for curved surfaces and small & delicate

parts.

Features:

·

Data Widget, which allows results to be instantly transmitted to

any PC package such as Excel, Word, and SPC programs etc.

·

Bluetooth Compatibility that can transmit data to any

smartphone, tablet or PC.

·

USB results download to PC without the need to install software

Reading shown:

Gloss: A measurement proportional to the amount of light

reflected from a surface measured at 20° (high gloss)

Haze: (reflectance haze) an optical effect caused by microscopic

textures or residue on a surface.

RIQ: Used to quantify effects such as orange

peel and surface waviness. This new parameter gives higher resolution results

compared to Distinctness of Image

DOI: A measure of how clearly a reflected image will appear

in a reflective surface and better mimic’s human perception of surface texture,

especially on high quality finishes such as automotive paint finish.

RSPEC: The peak gloss value over a very narrow angle.

Rhopoint

IQ Flex 20 - http://www.rhopointinstruments.com/product/rhopoint-iq-flex-20/

Colour,

Depth and Clarity - [: Reflectivity is

the fraction of incident radiation reflected by a surface. In full generality

it must be treated as a directional property that is a function of the

reflected direction]

Are the three factors

Concours d’élégance judges look for when scrutinizing paint film surfaces. So

much depends on proper surface preparation, a clean and level surface, and

product clarity, which allow the natural properties of the paint to show

through, as without transparency the true colours of the paint surface cannot

be seen. Waxing a surface that has not been properly cleaned will only result

in a shiny layer over dull, dirty paint - not the deep smooth, optically

perfect crystalline shine that is obtainable

Gloss - is an

optical property, which is based on the interaction of light with physical

characteristics of a surface. It is actually the ability of a surface to

reflect light into a specular direction. The factors that affect gloss are the

refractive index of the material and the angle of incident lighting.

The oils

that are formulated in Carnauba waxes provide gloss, which causes jetting (a

‘wetting’ of the surface) this distorts the light reflectance, giving the

surface the ‘look’ of depth or liquidity (i.e. mirror in shallow water reflecting

a three-dimensional deep, rich colour)

Depth – (iridescence) occurs due to the internal reflection of

light within a transparent film or layer of material, where the thickness of

the film or layer is of the order of the wavelength of the incident light.

Where

the wavelength of the light matches or is a low multiple of the path length

through the layer it will re-emerge from the layer after a single reflection

but where the wavelength is different to the path length it will be

re-reflected within the layer until it emerges after several internal reflections.

Changing your viewpoint changes the path length through the layer and this

means that a different wavelength or colour of light will seem to be reflected.

Chromatics - the

science of colour is sometimes called chromatics. It includes the perception of

colour by the human eye and brain, the origin of colour in materials, colour

theory in art, and the physics of electromagnetic radiation in the visible

range (that is, what we commonly refer to simply as light).

Optical

depth-comes from an applied product that is

two-dimensional, so that light is reflected from both a high and low source,

the light waves are distorted (diffuse

reflection) which creates a three dimensional illusion of depth to produce

jetting (a rippling effect, the so-called ‘wet-look)

The oils that are formulated

in Carnauba waxes provide gloss, which causes jetting (a ‘wetting’ of the

surface) this distorts the light reflectance, giving the surface the ‘look’ of

rippling liquidity, like a mirror in shallow water reflecting a three-dimensional

deep, rich colour, in contrast, bees wax, paraffin and many synthetic waxes and

polymer sealants tend to occlude (cloud)

Shine

– a perfectly

‘flat’ levelled surface is obtained by polishing the paint surface. Shine an

easily understood concept of light reflection / refraction (in simple terms the

light reflectance from a mirror) I wanted to expand that concept so that the

shine would be optically perfect as well as multi-dimensional. The bright shine

of a polymer sealant is often criticized as being “sterile” (a flat

silvery-white reflection) good reflective properties but without ‘depth’ or

jetting (wet-look) of an organic wax.

- Optimising light refraction - apply

product in ‘direction of airflow’ to vertical surfaces roof to floor and

then left to right, on horizontal surfaces bumper to trunk and then left

to right, over-lapping panels to ensure complete coverage. Then apply in direction

of airflow, horizontal surfaces hood to trunk, vertical surfaces front to

back. This application technique affects the paints optical properties by

optimising light refraction and the reflectivity of the bodylines and

contours of the vehicle.

- The aesthetics- of a vehicles

appearance is very subjective to say the least, the only best wax or

sealant that really matters is what looks 'best' to you. In the final

analysis it all comes down to; 85% preparation, 5% product, 7% application

method and the balance is in the ‘guy’ of the beholder

- Optically Clarity – [: its refractive index (RI) allows a

majority of the incidental light to be transmitted]

[The

term ‘optical clarity’ is difficult to define, and the boundaries between

‘transparent’ or ‘clear’ and ‘translucent’ or ‘opaque’ are often highly

subjective. What is acceptable for one observer is possibly not acceptable for

another observer.] Zeus website

- An optically perfect

shine comes from a clean, clear (i.e. the applied products do not occlude

the surface underneath) prepared and level surface; it improves the

desired optical properties i.e. surface reflectance. The other

requirements are surface gloss, depth of shine and applied product

transparency (clarity), which allows all of the components of an optically

perfect shine to be visible.

- The best light reflection is obtained

from a perfectly flat highly reflective surface, i.e. glass over a silver

metallic material(a mirror)

- A polish would need to level a paint

surface; this will provide a surface without distortion

- To provide protection to our

theoretically perfectly distortion-free surface we would need to apply a

wax or a polymer sealant, which in turn would need to be optically clear

Shine is an easily understood

concept of light reflection / refraction (in simple terms the light reflectance

from a mirror) I wanted to expand that concept so that the shine would be

optically perfect (a majority of the incidental light is transmitted) as well

as multi-dimensional. The bright shine of a polymer sealant is often criticized

as being “sterile” (a flat silvery-white reflection) good reflective properties

but without ‘depth’.

A clean polished paint

surface will exhibit a bright shiny finish, which is great on light colour

paint. On darker colours I prefer not just a bright shine but rather a deeper,

darker gloss.

Similar to a car's black

paint rippling as if it was under water. Carnauba in today's wax formulas

functions as a carrier, it is used to keep the polymers and oils on your car's

surface. Only a small portion of your vehicle's shine comes from the

"wax" (i.e. carnauba) itself. Carnauba is translucent at best with

only minimal light reflection.

The oils that are formulated

in Carnauba waxes provide gloss, which causes jetting (a ‘wetting’ of the

surface) this distorts the light reflectance, giving the surface the ‘look’ of

a mirror in shallow water reflecting a three-dimensional deep, rich colour, in

contrast, bees wax, paraffin and many synthetic waxes and some polymer sealants

tend to occlude (cloud) the finish

The aesthetics- of

a vehicles appearance is very subjective to say the least, the only paint

protection finish that really matters is what looks 'best' to you. In the final

analysis it all comes down to; 85% preparation, 5% product, 7% application method and

the balance is in the ‘guy’ of the beholder

In obtaining the ‘optically

perfect shine’ we should be equally concerned with ease of application,

resistance to abrasion, atmospheric contamination and weathering. Products

should be chosen that would carefully balance each of these considerations

without focusing on one specific characteristic. A surface protection with a

spectacular shine but limited durability just doesn’t make sense.

a) Requirements:

·

Clean-washed to remove oxidation, surface dirt and grime, tar

and road film

·

Reflectivity – that comes from a clean and level surface

·

Gloss-that comes from oils and polymers with their ability to

reflect light with a minimum of light diffusion to produce surface shine

·

Optimising light refraction -apply product in ‘direction of

airflow’, horizontal surfaces hood to trunk, vertical surfaces front to back.

This application technique affects the paints optical properties by optimising

light refraction and the reflectivity of the bodylines and contours of the

vehicle

·

Transparency-or clarity of the applied product, which will

enable all the above components to be clearly visible

b)

Contributing factors:

·

Cleaned-

using a mildly alkaline (pH 7.5) car wash concentrates to remove surface road

dirt and grime and then- using detailer’s clay to remove ingrained pollution

from the paint surface, and a chemical paint cleaner (Klasse

All-In-One) to prepare the surface for a polymer sealant and a Carnauba

wax.

·

Polished-removal

of minor blemishes, surface scratches, swirl marks and water marks with an

abrasive machine polish or compound (Menzerna) to

provide a level surface. A machine polish should remove surface imperfections

and swirl marks, contain oils for lubrication and should not leave residue that

requires extensive ‘clean-up’ to remove hazing, its solvents should evaporate

moderately quickly without leaving excess wax/oils behind, and lastly should

buff relatively easily.

·

Glazed- to

obtain a high gloss by providing the necessary oils and burnishing the paint

surface to a high optically clear gloss

·

Protected- the

polymers carrier system (solvents) allows the product to fill and level the

paint film surface to produce an ultra-flat surface while proving durable

surface protection. A polymer (Zanio Z2PRO™)

with its levels of shine, gloss, clarity, reflectivity, depth and 99% optical

clarity, which doesn’t distort or detract from the paints colour or lines of

the vehicle.

·

Waxed-the

applications of Carnauba (Souverän Paste Wax)

that will provide oils to provide a ‘wet-look’ to the surface and will also

provide a transparent surface when layered without yellowing or discoloration,

with a depth of shine by providing a two-dimensional surface.

·

Light

coloured paint -i.e. Silver, White, etc. (the exception is speed yellow) will

never obtain jetting (the so called ‘wet-look’) of black or dark colours

as they do not exhibit visible depth,

light colours tends to reflect light instead of absorbing it and providing a

2-dimentional look. You can obtain a good gloss provided the paint is good

quality and if it’s prepared and detailed correctly; washed, cleaned, polished

and a polymer sealant added (Zaino or

Klasse AIO and SG, Jeffswerkstatt - Acrylic Jett ) these

sealants will provide a flat silvery-white shine, but without ‘depth’ the

exception is Zaino Clear Seal

(Z-CS).

Bibliography

1.

Gloss as an aspect of the measurement of appearance by W Ji, MR

Pointer, RM Luo, J Dakin

2.

Surface correlation effects on gloss by R Alexander-Katz, RG

Barrera - Journal of Polymer Science

Copyright

© 2002-2010, TOGWT ® Ltd (Established 1980) all rights reserved